Flexographic printing, as an environmentally friendly printing method, is gradually replacing the traditional gravure printing. Especially in the current environment where environmental policies are continuously tightening, many printing enterprises that previously used gravure printing have begun to transform. According to relevant data, the quantity of gravure printing is gradually declining, while flexographic printing, in contrast, is continuously growing, replacing the original gravure market. Religious book printing. What reasons have led to this situation? From the perspective of printing enterprises, what are the advantages of flexographic printing? Let’s take a look together.

Flexographic printing, as the name suggests, is a type of flexographic plate made of materials such as resin. It is a relief printing technology, and the cost of plate making is much lower than that of gravure printing plates such as copper plates. This printing method was proposed in the mid-20th century. shopping bag printing. However, at that time, the supporting technology for water-based inks did not develop significantly, and environmental requirements were not as stringent as they are now, so it was not widely promoted in the printing of non-absorbent materials.

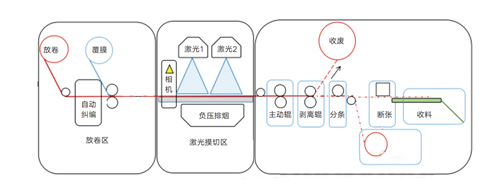

Although flexographic printing and gravure printing are basically the same in terms of processes such as unwinding, printing, inking, drying, etc., there are still significant differences between the two in detail. In the past, gravure printing, coupled with solvent-based inks, had significantly better printing effects than flexographic printing. catalogue printing. Now, with the significant development of environmentally friendly inks such as water-based inks and UV inks, the advantages of flexographic printing are beginning to show, which are not inferior to gravure printing. In general, flexographic printing has the following characteristics:

-

Lower cost: The cost of plate making is much lower than that of gravure, especially for small batch printing, the difference is significant.

-

Less ink consumption: Flexographic printing uses flexographic plates and ink transfer via anilox rolls, reducing ink consumption by over 20% compared to gravure printing.

-

Faster printing speed, higher efficiency: Flexographic printing machines, when combined with high-quality water-based inks, can easily achieve speeds of 400 meters per minute, while common gravure printing often only reaches 150 meters per minute. China printing.

-

More environmentally friendly: Flexographic printing generally uses environmentally friendly inks such as water-based inks and UV inks, which are more environmentally friendly than the solvent-based inks used in gravure printing, with almost no VOC emissions, achieving food-grade safety standards.

Characteristics of Gravure Printing:

-

Higher plate making costs: Early gravure printing used chemical corrosion methods for plate making, which was not very effective. Now, laser plate making can be used, resulting in higher precision. Additionally, plates made of metals such as copper are more durable than flexible resin plates used in flexographic printing, but the plate making costs are higher, leading to higher initial investment. Click to learn more about textbook printing.

-

Better printing accuracy and consistency: Metal plates are more suitable for large volume printing and offer better consistency, with minimal impact from thermal expansion and contraction.

-

Higher ink consumption, higher production costs: In terms of ink transfer, gravure printing consumes more ink, which invisibly increases production costs.

Comments

No comments yet. Be the first to react!